Technical

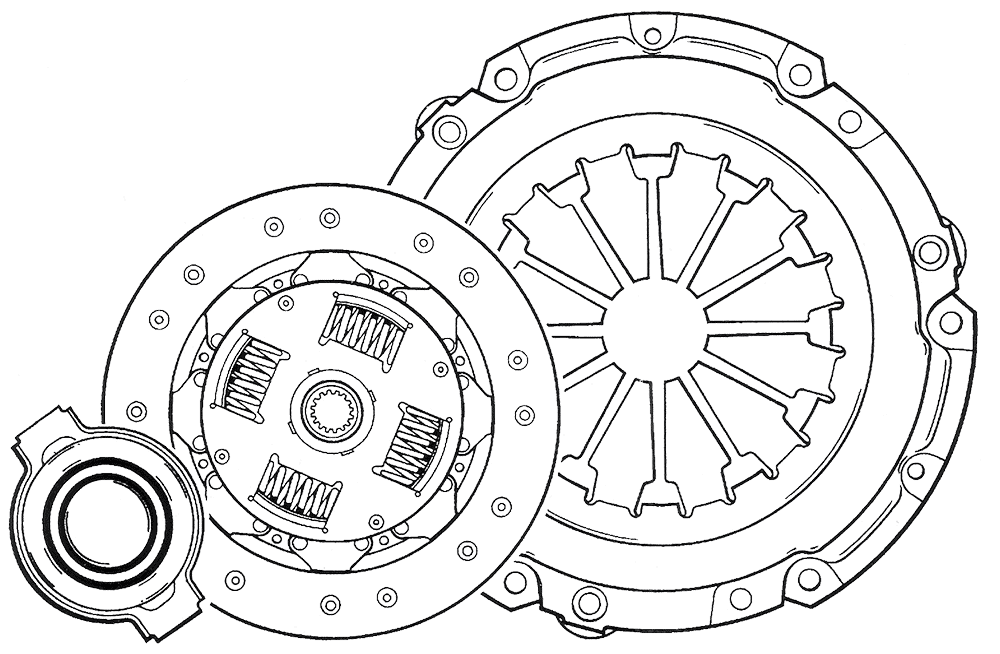

Remanufactured Clutches Supplier in the UK

Fleetway is Highly experienced and can fulfil any order requirement large or small.

Fleetway are proud to be recognised as leading experts in the clutch remanufacturing industry. We implement technologically advanced processes and specifications that ensure that our finished remanufactured products function equally well as original equipment products.

The entire clutch remanufacturing production process

…is carried out on dedicated and specialised in-line equipment which facilitates volume and small batch flow production. Fleetway only chooses original equipment core for remanufacturing. If the selected core is visually found to be serviceable after the initial cleaning, all component parts are further examined and tested before being dismantled for refinishing and machining.

As the component parts are processed, they undergo stringent examination, measurement and mechanical testing. All worn, damaged or substandard parts are discarded and replaced with new parts as required.

We ensure clutch production and quality is consistent and controlled

All lever-type units are assembled, activated, lever height set and then activated and reset again. This assembly and testing are carried out on purpose-built precision equipment to ensure total accuracy in the setting.

Other Details

Final assembly of clutch driven plates

All lever type units are assembled, activated, lever height set and then activated and reset again. This assembly and testing is carried out on purpose built precision equipment to ensure total accuracy in setting.

We ensure clutch production and quality is consistent and controlled

Carried out on automatic riveting equipment, and primarily only high quality ‘asbestos free’ VH-03 friction material manufactured by Frenos Sauleda, and which compares to original equipment specification material is selected and used on driven plates ensuring smooth clutch control and long clutch life.

After final clutch assembly

Every clutch component is tested on specialised test equipment and computer analysed to determine that its function and activation performs within the specific tolerances that have been acquired by us after the testing and appraising original equipment components.

Having remanufactured over 4,000,000 clutch components

Fleetway has seen the resultant wear characteristics of those worn exchange units and has noted the various strengths and weaknesses of the very many different clutch design types that are manufactured.

It is that acquired knowledge that places Fleetway in the prestigious situation of knowing what improvements if any are required during the remanufacture of a clutch to ensure it will function perfectly, and last as long as an original manufacturers unit, if not longer.